ZJ70DB electric control system

2016-08-04 16:08 Click£ºtimes

2000HP ZJ70DB AC rig123.net' target='_blank'>VFD Electric Modular rig123.net' target='_blank'>Drilling Rig

General Description

· Hook load: 1,000,000 lbs, 500 US ton (4500KN) with 12 lines.

· Setback capacity: 386,000 lbs, 193 US ton (1717KN).

· Simultaneous hook load and setback capacity: 1,376,000 lbs, 688 US ton (6120KN).

· Static Rotary beam capacity: 1,000,000 lbs, 500 US ton (4500KN)

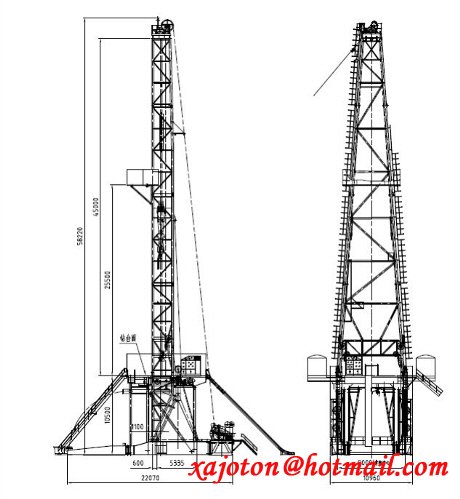

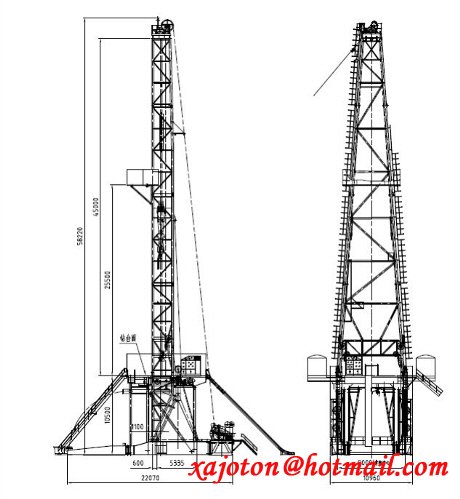

· Mast type: K Type mast open fronted 147.6 ft, adjustable monkey board 74ft-87ft with SALA Geronimo Escape system.

· Substructure type: Parallelogram swing up integrated raising substructure with rig floor.

· Depth rating: 4 ½” Drill pipe: 22,967 ft (7000M), 5” DP 19,686 ft (6000M).

· Wind speed: No hook load & no pipe in set back: 107 mph (172 km/h), No hook load & set back full of drill pipe: 80 mph

(130 km/h).

· Rig floor height: 34.4 ft (10.5 M).

· Clear height below rotary beams: 29 ft (8.9M).

· Rotary table size: 37.5”.

· Drill line size: 1 ½ in (38mm).

· Draw works: JC70DB 2000hp (1490KW), Disc brake, dual AC VFD drive motors and single speed transmission.

Regenerative braking.

· Catheads: Model YM16, rated at 36,000 ft lbs straight pull.

· Rig floor total area: 40 ft X 34.6 ft, (12.25m x10.55m).

· Air winches: 2 x 5T air winches on rig floor, 1 at the end of the catwalk and the monkey board has 2 x 0.5T air winch.

· Martin Decker RigSense 2.0 drilling instrumentation system.

· Gaitronics rig site communications system

· Mathey wireline unit complete with Totco 8 and 16 degree survey equipment.

· Operating temperature: -20°C to +55°C (cold weather or desert modifications on request)

Top Drive

· TDS and drive unit: Tesco 500 ECI 900 Top Drive system, complete with electrical and hydraulic control systems. Guide rail, shipping containers, spares, tools and operation manuals.

Power Package

· Type and rating of generator sets: 4 x Cat 3512B 1200KW c/w 1500KVA generator.

Electrical System

· Power system 600v, 50 Hz for VFD drives. 400V 50 Hz for DC Motor control and 230v 50 Hz for solids control system, lighting and general power (60Hz system also available).

Control System

· Stainless steel clad Drillers cabin.

· High tech PLC control system is utilized to give precise control of the Variable Frequency Drives (VFD) to operate all rig functions.

· Driller control system employs a drillers chair with two joysticks to control draw works hoisting and lowering, the second to apply and release the disc brakes.

· The driller controls the major rig functions such as the Mud Pumps and the Top Drive via simple, user friendly touch screen terminal and switch panels mounted within easy reach and view of the drillers chair.

· Driller’s cabin console also houses all other interface devices such as video system monitor, intercom system, instrumentation system, hydraulic weight indicator and stand pipe pressure gauges.

Mud Pumps

· Mud Pumps: Qty 3 x 1600HP triplex pumps c/w liner wash and charge pumps, Suction strainer, dampener and pulsation dampener, reset relief valves with integrated bleed and relief valve line.

BOP and Control system

· Shenkai 13-⅝” 5K Annular BOP, 13-⅝” 10K Double Ram, Drilling Spool, 13-⅝” 10K Single Ram. Ram blocks included. BOP Test Pump, (air powered) with hoses and chart recorder. BOP Test Base. BOP Stack Lifting device. Transport Skid. BOP Control Unit. BOP Control Unit remote Panel, (For Drill floor) Transport Skid for above control units. Choke and Kill Manifold 3-1/16” X 10K. 3-1/16” X 10K Manual and Hydraulic valves. JY-70A Remote Choke panel. DSA. 2-1/16” 10K Non-return Valve. Complete with high pressure fire proof hydraulic hoses and hand wheels (15k available on request).

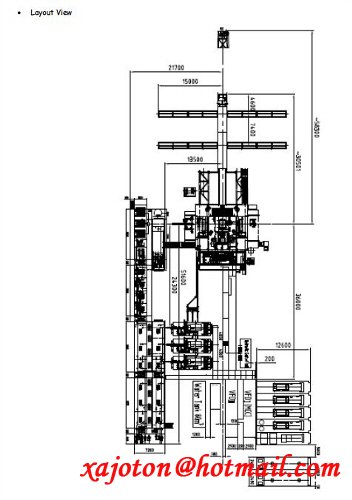

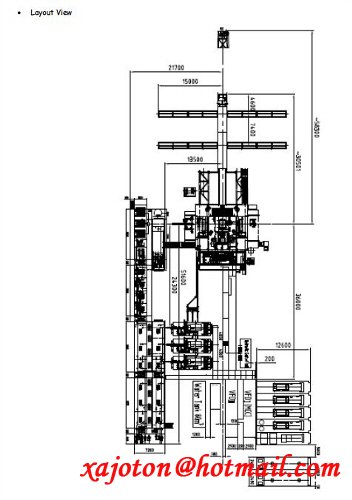

Solids Control System

· BBL capacity: 2,160 BBL (343M³) system. Six tank with additional brake cooling water tank and trip tank

· 3 each Brandt King Cobra Linear Shale Shakers with 3rd shaker incorporating 1 each Brandt King Cobra Mud Cleaner (16 x 4” de-silter cones rated for 1000GPM and 2 x 12” de-sander cones rated for 1000GPM).

· Qty 1 Ea Model Brandt DG-12 Vacuum Degasser with 5 hp, 50 hz, 230/460 volt, 3 phase, explosion proof electric motor rated for 1200 GPM complete with JP-12 Jet Pump Eductor.

· Mix hopper: Qty 2 DN150 x Jet hoppers.

· 18 total. 17 x HM-15, 20 hp (15KW) and 1 x 7 hp (5.5 KW).

· Mud Guns: Qty 17- mud guns supplied.

· Centrifugal pumps: Qty 2- 6 x 8 x 12 1/2” impeller, 100 hp (75KW) (de-silter, de-sander pumps).

· Centrifugal pumps: Qty 2- 6 x 8 x 13” impeller, 100 hp (75KW) (mix pumps)

· Centrifugal pumps: Qty 3- 6 x 8 x 13” impeller, 100 hp (75KW) (charge pump)

· Centrifugal pumps: Qty 2- 3 x 4 x 9” impeller, 15 hp (11KW) (water pump)

· Centrifugal pumps: Qty 2- Cooling pumps.

Auxiliary Tanks

· Water tank: 500 bbl (79.6m3)including 2 x pumps

· Diesel Fuel tank: 377 bbl (60m3) including 2 x transfer pumps

· Diesel day tank: 280 bbl (44.5m3).

· Oil tank: 95 bbl (15m3)

Handling Tools and Equipment

· Drill pipe and casing elevators, Bails, Slips for drill pipe and casing, Manual drill pipe and casing tongs, Pipe spinner, Casing power tong, Hydraulic unit, Swivel/Kelly unit with drive bushings, rotary table bushings and inserts, pipe racks, bit breakers.

Air System

· Air Compressors: Qty 2 x LS16-75 Sullair 75 hp rated at 300cfm, includes cold start compressor.

· Air Drier: Model: IR142EDC, Capacity: 500 CFM

· Air Receivers: 2 x 88 cubic feet receivers at compressor house and 1 x 115 cubic feet receiver at sub structure.

Rig Move

· Weight and Dimensions of largest load: Draw works package 48½T(US), 37¾’L x 11’W x 9½’H (11.5m x 3.4m x 2.9m)

· Rig move time required: 10 - 12 days.

TAG£º

General Description

· Hook load: 1,000,000 lbs, 500 US ton (4500KN) with 12 lines.

· Setback capacity: 386,000 lbs, 193 US ton (1717KN).

· Simultaneous hook load and setback capacity: 1,376,000 lbs, 688 US ton (6120KN).

· Static Rotary beam capacity: 1,000,000 lbs, 500 US ton (4500KN)

· Mast type: K Type mast open fronted 147.6 ft, adjustable monkey board 74ft-87ft with SALA Geronimo Escape system.

· Substructure type: Parallelogram swing up integrated raising substructure with rig floor.

· Depth rating: 4 ½” Drill pipe: 22,967 ft (7000M), 5” DP 19,686 ft (6000M).

· Wind speed: No hook load & no pipe in set back: 107 mph (172 km/h), No hook load & set back full of drill pipe: 80 mph

(130 km/h).

· Rig floor height: 34.4 ft (10.5 M).

· Clear height below rotary beams: 29 ft (8.9M).

· Rotary table size: 37.5”.

· Drill line size: 1 ½ in (38mm).

· Draw works: JC70DB 2000hp (1490KW), Disc brake, dual AC VFD drive motors and single speed transmission.

Regenerative braking.

· Catheads: Model YM16, rated at 36,000 ft lbs straight pull.

· Rig floor total area: 40 ft X 34.6 ft, (12.25m x10.55m).

· Air winches: 2 x 5T air winches on rig floor, 1 at the end of the catwalk and the monkey board has 2 x 0.5T air winch.

· Martin Decker RigSense 2.0 drilling instrumentation system.

· Gaitronics rig site communications system

· Mathey wireline unit complete with Totco 8 and 16 degree survey equipment.

· Operating temperature: -20°C to +55°C (cold weather or desert modifications on request)

Top Drive

· TDS and drive unit: Tesco 500 ECI 900 Top Drive system, complete with electrical and hydraulic control systems. Guide rail, shipping containers, spares, tools and operation manuals.

Power Package

· Type and rating of generator sets: 4 x Cat 3512B 1200KW c/w 1500KVA generator.

Electrical System

· Power system 600v, 50 Hz for VFD drives. 400V 50 Hz for DC Motor control and 230v 50 Hz for solids control system, lighting and general power (60Hz system also available).

Control System

· Stainless steel clad Drillers cabin.

· High tech PLC control system is utilized to give precise control of the Variable Frequency Drives (VFD) to operate all rig functions.

· Driller control system employs a drillers chair with two joysticks to control draw works hoisting and lowering, the second to apply and release the disc brakes.

· The driller controls the major rig functions such as the Mud Pumps and the Top Drive via simple, user friendly touch screen terminal and switch panels mounted within easy reach and view of the drillers chair.

· Driller’s cabin console also houses all other interface devices such as video system monitor, intercom system, instrumentation system, hydraulic weight indicator and stand pipe pressure gauges.

Mud Pumps

· Mud Pumps: Qty 3 x 1600HP triplex pumps c/w liner wash and charge pumps, Suction strainer, dampener and pulsation dampener, reset relief valves with integrated bleed and relief valve line.

BOP and Control system

· Shenkai 13-⅝” 5K Annular BOP, 13-⅝” 10K Double Ram, Drilling Spool, 13-⅝” 10K Single Ram. Ram blocks included. BOP Test Pump, (air powered) with hoses and chart recorder. BOP Test Base. BOP Stack Lifting device. Transport Skid. BOP Control Unit. BOP Control Unit remote Panel, (For Drill floor) Transport Skid for above control units. Choke and Kill Manifold 3-1/16” X 10K. 3-1/16” X 10K Manual and Hydraulic valves. JY-70A Remote Choke panel. DSA. 2-1/16” 10K Non-return Valve. Complete with high pressure fire proof hydraulic hoses and hand wheels (15k available on request).

Solids Control System

· BBL capacity: 2,160 BBL (343M³) system. Six tank with additional brake cooling water tank and trip tank

· 3 each Brandt King Cobra Linear Shale Shakers with 3rd shaker incorporating 1 each Brandt King Cobra Mud Cleaner (16 x 4” de-silter cones rated for 1000GPM and 2 x 12” de-sander cones rated for 1000GPM).

· Qty 1 Ea Model Brandt DG-12 Vacuum Degasser with 5 hp, 50 hz, 230/460 volt, 3 phase, explosion proof electric motor rated for 1200 GPM complete with JP-12 Jet Pump Eductor.

· Mix hopper: Qty 2 DN150 x Jet hoppers.

· 18 total. 17 x HM-15, 20 hp (15KW) and 1 x 7 hp (5.5 KW).

· Mud Guns: Qty 17- mud guns supplied.

· Centrifugal pumps: Qty 2- 6 x 8 x 12 1/2” impeller, 100 hp (75KW) (de-silter, de-sander pumps).

· Centrifugal pumps: Qty 2- 6 x 8 x 13” impeller, 100 hp (75KW) (mix pumps)

· Centrifugal pumps: Qty 3- 6 x 8 x 13” impeller, 100 hp (75KW) (charge pump)

· Centrifugal pumps: Qty 2- 3 x 4 x 9” impeller, 15 hp (11KW) (water pump)

· Centrifugal pumps: Qty 2- Cooling pumps.

Auxiliary Tanks

· Water tank: 500 bbl (79.6m3)including 2 x pumps

· Diesel Fuel tank: 377 bbl (60m3) including 2 x transfer pumps

· Diesel day tank: 280 bbl (44.5m3).

· Oil tank: 95 bbl (15m3)

Handling Tools and Equipment

· Drill pipe and casing elevators, Bails, Slips for drill pipe and casing, Manual drill pipe and casing tongs, Pipe spinner, Casing power tong, Hydraulic unit, Swivel/Kelly unit with drive bushings, rotary table bushings and inserts, pipe racks, bit breakers.

Air System

· Air Compressors: Qty 2 x LS16-75 Sullair 75 hp rated at 300cfm, includes cold start compressor.

· Air Drier: Model: IR142EDC, Capacity: 500 CFM

· Air Receivers: 2 x 88 cubic feet receivers at compressor house and 1 x 115 cubic feet receiver at sub structure.

Rig Move

· Weight and Dimensions of largest load: Draw works package 48½T(US), 37¾’L x 11’W x 9½’H (11.5m x 3.4m x 2.9m)

· Rig move time required: 10 - 12 days.

TAG£º